Problem With Code Compliance

The problems with complying with the current code requirements are:- The codes do not define how many devices are required.

- The codes do not specify the factor of safety required for positive attachment devices.

- The electrical code permits bolts and screws, whereas the building code only permits devices. A few decades ago, lighting fixture housings were manufactured as one single integral unit. The practice of bolts and screws may be suitable for these types of light fixtures, as the housing unit could not come apart. However, today the light fixtures are manufactured from an assembly of components, the main housing with two end plates loosely clipped to the housing unit with minimal structural integrity. These light fixture end plates can detach from the main housing when a load is applied to the end plates. Therefore attaching the light fixture by bolts and screws via connections at the end plates does not meet the intent of the code.

- Industry has generally ignored the required code structural capacity definition of the two hanger wires. Each hanger wire shall be capable of carrying not less than 100 pounds with a factor of safety of 3 (UBC Standard 25-2 Section 25.212.1 & IBC Reference ASCE 7 Reference CISCA 3 & 4 Installation). The hanger wire meets this requirement, provided the connection to the light fixture housing has a proven load capacity. The video at the right shows static load tests performed on lighting fixtures with and without SFCs. Many installations have the hanger wires connected to tabs on the end plates, the end plates can detach from the light fixture main housing at very low load levels. No seismic restraint.

- During an earthquake event the code intends for the suspended ceiling system to move laterally, without unintended impediment from the light fixtures. This is the primary reason for the two additional hanger wires to be “slack”. Most wires are installed out-of-plumb due to the general misalignment between the wire attachments at the structure above and at the fixture positions. Given this, if the two hanger wires were attached snugly, with an initial tension, the hanger wires could act as tension braces and inadvertently restrain the movement of the ceiling. The resulting pounding between the light fixture and the T-bar runners could cause failure of the light fixture attachment at the T-bar runners. Continued cyclical seismic movements could cause dislodging of the light fixtures, main runner/cross runner to disconnect, as well as damage to other non-structural components like sprinkler heads.

In view of these problems, ICC Acceptance Criteria (AC184) defines the structural requirements for Positive Attachment devices and the two slack wires as intended by the code. Additionally AC184 provides a positive attachment test criteria that can substitute for the two slack wires attached to the light fixture housing.

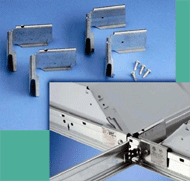

The lighting fixture is suspended to the ceiling grid by Seismic Fixture Clamps (SFC) at all four corners to ensure that it is earthquake safe.

Static load test